Installing Smarter

Every brand of hardwood has specific instructions and recommendations for installing. This includes the type of glue assist needed, type of fasteners, and how far to space the wood and nails from one another. One thing we avoid in every floor are the prominent appearance of “Hs” and “Staircasing.” An “H” joint is where two end joints appear opposite of each other, which gives the appearance of the letter H. A “Staircase” is when the wood is installed on top of each other creating the appearance of a staircase. In most cases, mills recommend avoiding both for proper warranty and installation. Another thing we focus on when installing is avoiding top nailing unless it’s absolutely necessary. When approaching walls, we avoid leaving wood-filled holes on top of your new floor by gluing the perimeter of floor to the ground. These little steps ensure proper tension across boards, maintain manufactures warranty, and keep your new floors looking beautiful.

Type of Finish Matters

There are countless options of floor finish when staining or coating hardwood. We encourage customers to know the basics about floor finish before deciding on one. At Perennial Hardwood, we have recommended options, with each option varying in color, ingredients, and durability. Generally, we encourage use of our two-component commercial grade water-based finish. By using a commercial grade product for your home, we can ensure it will provide better durability and value during the life of your floor. This option is perfect for rentals, kids, and pets. Single component finishes offer great quality and build but are not cost effective after more than a couple years. The final finish option is a penetrating oil that allows for unique colors, easy repairs, and no VOC formulation. This oil is 100% natural and is more durable than most single component finishes. Refer back to our finish options to compare our different types of finish.

Perennial Hardwood Finish Options-PDF

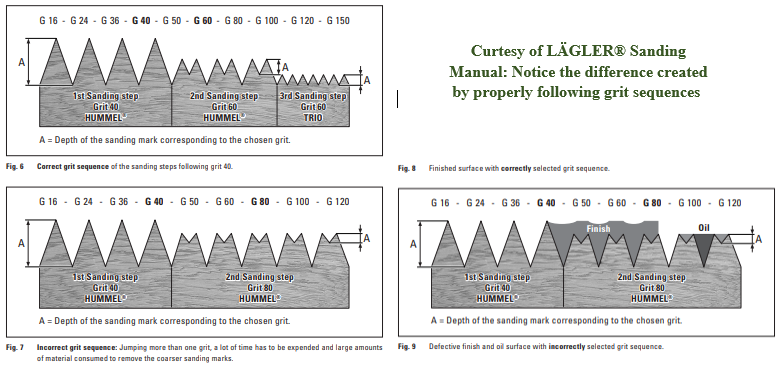

The Holy Grail: Grit Progression

Perhaps the most important process of sanding a hardwood floor is the “grit progression” process. A “grit” describes the coarseness and abrasiveness of sandpaper. Per PST (Premium Sanding Technology) and NWFA (National Wood Floor Association) standards, we are required to skip no more than one grit when sanding a floor. This means out of a range of 24, 36, 40, 50, 60, 80, 100, and 120 grits, it is recommended that no more than one consecutive grit be omitted from the process. By not skipping more than one grit (ie. 40grit to 80grit), we guarantee to always keep “high peaks” at a minimum, which allows for an equal distribution of finish across the floor.

When a floor has less finish on top because of an incomplete sanding process, the durability is significantly reduced. We promise to always put our grit progression IN WRITING before starting your project. We understand your time and money matter. We will always give 100% effort in everything we do to make sure your floor lasts as long as possible. These three quality differences are our promise when refinishing or installing any sand-on-site product.